Prilep Brewery was founded in 1924. This period is characterized by manual production, which grows from year to year and reaches up to 8,000 hectoliters of beer per year at the beginning of the Second World War. With the assumption of leadership by young, highly educated staff, the rapid growth of Prilep Brewery – Prilepska Pivarnica began in 1975. Over the next three years, production jumped to 250,000 hectoliters of beer per year.

In 2000, it launched the “Zlaten Dab” beer. Since the appearance of Zlaten Dab, the equipment has been installed in the Brewery for full and automatic management of the beer fermentation process, fully sterile production of brewer’s yeast, and automatic washing of all equipment and installation.

In 2003, the second phase of the investment project was implemented, which concerned capacity expansion. That expansion included six new fermentation vessels, additional equipment in the brewing compartment for the beer malt, and additional packaging.

In 2007, Prilep Brewery – Prilepska Pivarnica carried out a complete reconstruction, expansion, and full automation of the “brewery of beer” department to maintain the quality of its product and respond to the request for its permanent presence on the market. At the beginning of 2009, 16 cylindrical-conical tanks were procured with a total capacity of up to 500,000 hectoliters to accommodate the beer during its stabilization and maturation in production. In this way, the capacity of the summer basement is also increased, which means the possibility of increased production with standard high quality.

In 2011, the Prilep Brewery – Prilepska Pivarnica invested in acid-free filtration. With this investment, the Brewery has become one of the three in Europe and the only one in the region that owns this equipment, which protects the environment – there is no waste after filtration. Namely, membrane filters are placed where the fine particles of yeast and protein sediment are processed. The new way of filtration also allows constant stabilization of the beer to reduce the ingredients that affect the beer’s bitterness, resulting in pure bitterness. The investment represents the completion of the entire beer production process, fully automated and computerized.

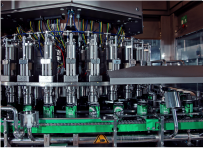

In 2013, 7.5 million euros were invested in a new line for filling beer and carbonated beverages in glass packaging. This is the largest investment in the brewery in a year. The new investment is a line for filling drinks in glass packaging consisting of 15 machines procured from the most famous company of its type – Crones from Germany. This is the only type of equipment in Macedonia. With this investment, approximately 30 million euros have been invested in the last ten years in Prilep Brewery – Prilepska Pivarnica, primarily in equipment for beer filtration and stabilization or known as unsealed filtration, water treatment equipment, for aging, maturation, and stabilization of beer, investments in new products and more.

The Path of Quality and Tradition from 1924 until today

With continuous investment in the production process since its establishment in 1924 until today, "Prilepska Brewery - Prilepska Pivarnica " constantly improves the quality of its existing products and creates new ones.

HOW WE STARTED

1924

STEAM BOILER

1953

A steam boiler is installed to brew the beer.

2000

CAPACITY EXPANSION

2003

FULL AUTOMATION

2007

CAPACITY INCREASE

2009

ACID-FREE FILTRATION

2011

LARGEST INVESTMENT

2013

THE BREWERY TODAY

2023